EGR systemgeneration of NOX

NOX origins from the three channels below:

- 1.NOX: it generated oxygen atoms (& molecules) and hydrogen atoms(& molecules) by decomposition reaction during the high temperature(burning), these atoms and molecules are jointed to NOX according to Zeldovich theory

-

- 2.¡°instant ¡± NOX: it generated HC root during the poor oxygen flame zone of premixed burning, it formed cyanide by combined with hydrogen molecules, then formed NOX through secondary reaction from cyanide.

-

- 3.¡°fuel¡± NOX: it formed NOX from the separated nitrogen at the fuel boundary zone during the burning of relative low temperature.

Usually, high temperature NOX occupied main role in Disel, the other NOX are insignificant. Now, the widely accepted explanation of NOX is the Zeldovich theory, the reaction is:

O2¨T¨T2O ¡¡¡¡¡¡¡¡¡ (1)

O+N2¨T¨TNO+N ¡¡¡¡¡¡¡ (2)

N+O2¨T¨TNO+O ¡¡¡¡¡¡¡¡(3)

Where Kr1¡Ô7¡Á1013 exp 76800 / RT

Kb1¡Ô1.55¡Á1013

Kr2¡Ô13.3¡Á109 Texp 7080 / RT

Kb2¡Ô3.2¡Á109 Texp 39100 / RT

Chain reaction starts from the oxygen atom of reaction equation, this oxygen atom is formed from the decomposition of oxygen(reaction equation 1) during the high temperature of burning. After the reaction, molecular nitrogen and atom oxygen or molecular oxygen crashed into NO(reaction equation 2 ,3).

The little oxygen atom of left reaction equation 2 is supplied by the right nitrogen of reaction equation, the NO formed by the reaction equation 2&3 is the same magnitude.

It can see from the above chain reaction, the condition of mainly influenced NOX generation is high temperature and rich oxygen, nitrogen and oxygen can generate chemical reaction only at the high temperature and high pressure, the temperature and pressure at the combustion chamber meet the above condition, compulsory acceleration is especially true. Except for HC, CO, CO2, SO2 etc.

the harmfulness of NOX

The nitrogen oxides of vehicles wasted gas exhausts to the air, it forms photochemical fog when meets the intense ultraviolet. This photochemical fog can cause eyes ache, even though out of breath. If breathe the air polluted by nitrogen oxides and black smoke all along, this may cause the disease of respiratory organs and cancer, NOX destroyed our environments severely, the city of densely population is prominent especially.

inevitability of control emission

With the steep rise of all the countries vehicle-owned, the air pollution of exhaust emission has been increasing serous, and this has been the main pollution source of the city air. With the importance of environmental problem has been increasing gradual, the view of reducing the engines emission has been the important direction of engines development in the world. With the rise of the consumption of world¡¯s petroleum products, oil price was kept high, the economy of Disel & gasoline vehicles becomes more and more prominent, this made Disel & gasoline as a vehicle motion plays the important role. So researching the harmful emissions of Disel & gasoline vehicles is the chief task of the designers, each country restricts the vehicle emissions strictly, it decides the important direction of automobile technology development is improving the emission and reducing pollution.

EGR is the abbreviation for English Exhaust Gas Recirculation, the means is exhaust gas recirculation. EGR technology is the effective method to reduce NOX, EGR technology is introducing the certain amount wasted gas into the inlet system, the proportion of inert gas, water steam, nitrogen, carbon dioxide is increase, because inert gas isn¡¯t take part in burning, and it has the high specific heat capacity, absorbs the emitted heat of burning, and it can increase the mixed gas specific heat capacity diluted from the recirculation, it decreases the high burning temperature of the engine. In the mean while, the entering of wasted gas will decrease the oxygen purity, and it destroys the formation conditions of NOX, reduces the formation quantity of NOX. but the entering of wasted gas, the emission of particles, carbon oxide and HC is increase, it may increase the specific oil consumption. So it must trade-off study between the decrease of NOX and the rise of the other emission index and economic index.

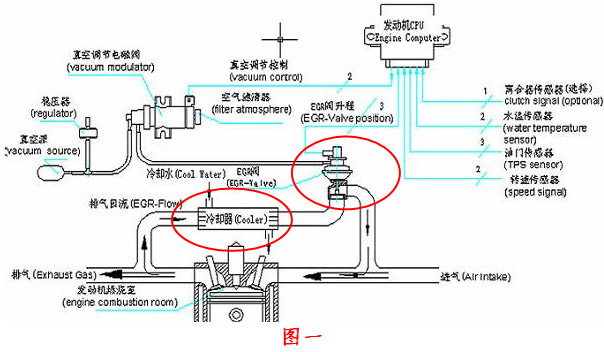

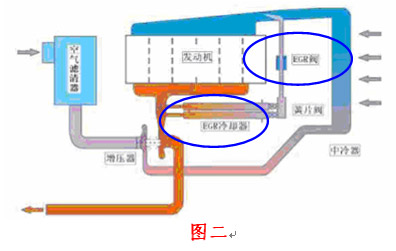

GR technology is divided into cool EGR and heat EGR according to the temperature of gas recirculation. Heat EGR can make the temperature of inlet pipe increase, and reduce the air fuel ratio gradually and increase the emission of particles. It also proved by test, the emission of soot, carbon oxide, carbon dioxide of heat EGR is higher than cool EGR. Reduced the emission of particles gradually on the basis of the decrease of NOX, now we adopt cool EGR method, that is installing a cooler on the EGR pipe, make the EGR temperature no more than 80¡æ. It is composed of EGR valve, EGR vacuum valve, EGR solenoid valve, ECM/PCM and EGR poppet sensor etc. it is a emit purifying device and aims at one of the harmful gas NOX of engine emission, principle diagram is shown below:

?Now Richleo majors in production the advanced engine EGR system, includes EGR cooler, EGR ECU, EGR valve, vacuum solenoid valve, metal honeycomb carrier and heat exchanger etc.

EGR cooler

EGR cooler is a new environmental product, installed at the vehicle EGR system used to cool the back flow wasted gas. EGR system is a technology and method of decrease NOX emission of vehicle. In order to meet the European ¢ô&¢õof vehicle tail gas emission, it must adopt this product, nowadays, it has only several factories can product batch in the country. This product is the important developing one of development and reform commission of¡¶vehicle components ¡°eleventh five year¡± special development plan of China¡·, so we seized this opportunity and put into massive funds, emphasis on development, the technology has been matured and always has been a inevitable purifying product of meeting the engine emission standard.

It will generate 500 to 600 centigrade high temperature during the burning, according to the above principle diagram, high temperature wasted gas back flow can not achieve the emission effect, it needs to cool the wasted gas and back flow and this is effective, and this course finished at the cooler. If not cool the EGR gas, high temperature gas back flow will heat the inlet gas, this will cause the greatly rise of the burning temperature and pressure in the cylinder, offset the action of EGR decrease NOX, it will destroy the structure of engine body at severe case, so it is necessary to cool the high temperature EGR gas through the cooler.

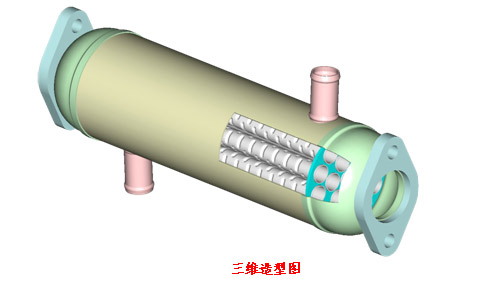

The object of EGR cooler is recirculation gas, the temperature is high, and requires heat exchanger realize the more heat transmission in the smaller heat exchange area, and accommodate the feature of engine great vibration. Our R&D department refers the advanced experience at home and abroad, analysis in many respects, develops the shell-and-tube heat exchanger, it made the thermal conduction excellent stainless steel 304 as carrier, it is high vacuum brazed from shell, helical groove tube, end-plate and joint flange, it proved by many tests, the structure is reasonable, each index are meet the requirements, such as heat elimination, vibration-proof, explosion-proof etc. it adapts to the environment of high temperature and high pressure, see the below diagram.

After the EGR system design and test, installs on the Disel, inspect the emission between the sample engine and our engine installed EGR system as a comparison, the result is below:

|

|

NOX |

HC |

CO |

PM |

|

European ¢ó standard |

5.0 |

0.66 |

2.1 |

0.13 |

|

Sample engine |

7.74 |

0.41 |

0.74 |

0.20 |

|

Installed EGR |

5.0 |

0.46 |

0.79 |

0.20 |

It seems that the Disel emission is decreased apparently after installed EGR system, it decreases by 12.9% and meets the requirements of European ¢ó standard, the emission of HC, carbon oxide slightly increased, but this controls within European ¢ó standard, because installed EGR at the full load condition, the emission of PM is slightly increased than the sample engine.

Synthetic conclusion:

EGR system of exact match and electric control can decrease the NOX emission effectively.